Novel techniques for cost-effective production of Bacillus thuringiensis Subsp. israelensis

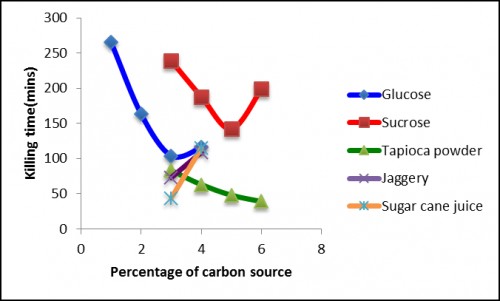

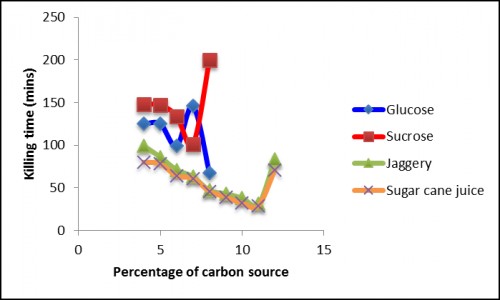

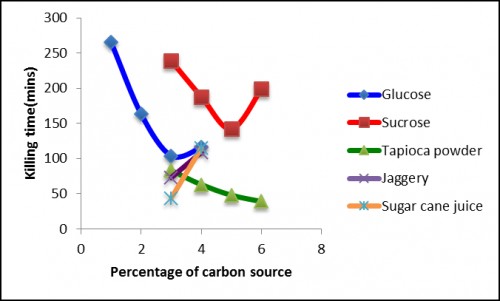

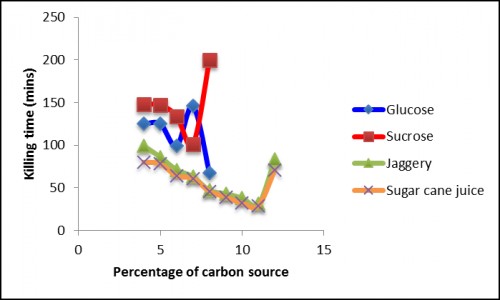

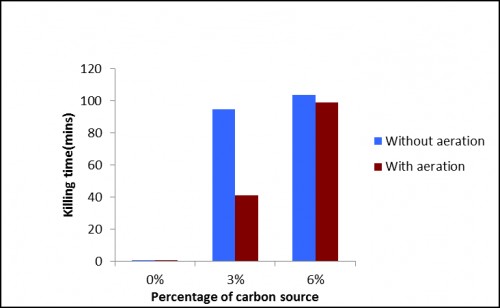

Fig. 1:

Fig. 1: Larvicidal activity of

Bacillus thuringiensis subsp.

israelensis for different carbon sources in batch fermentations. The figure also shows the different concentrations for each carbon source, at which the ‘crabtree effect’ is observed. Larvicidal effect is maximum at different concentrations for each of the sources used.

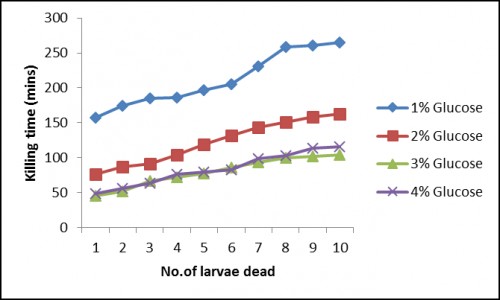

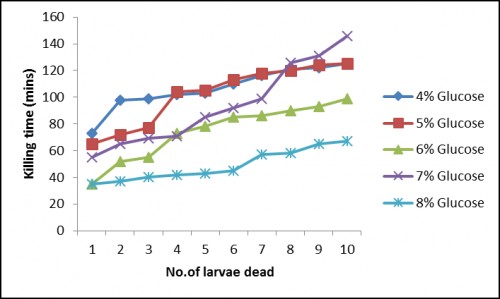

Fig. 2:

Fig. 2: Bioassay results of batch fermentation studies using different carbon sources (a) Glucose

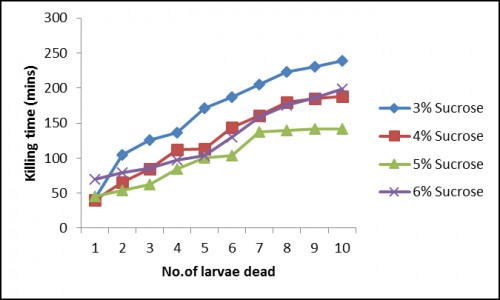

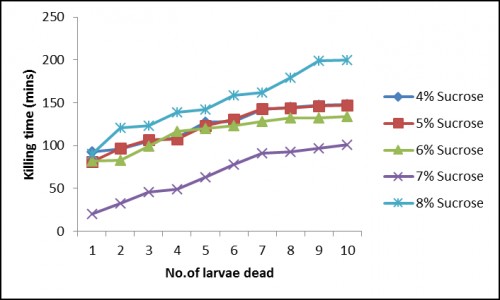

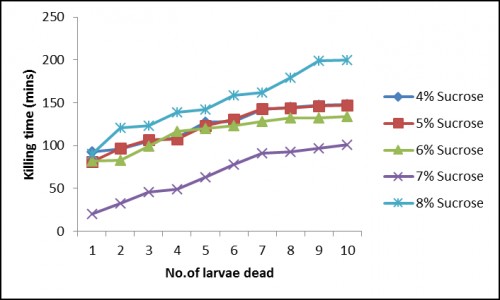

Fig. 3:

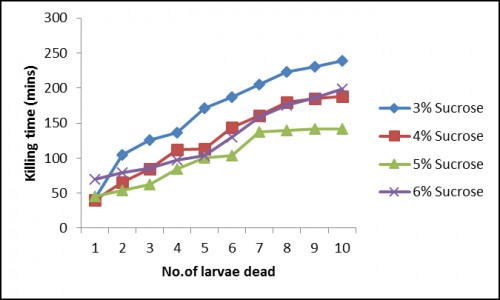

Fig. 3: Bioassay results of batch fermentation studies using different carbon sources (b) Sucrose

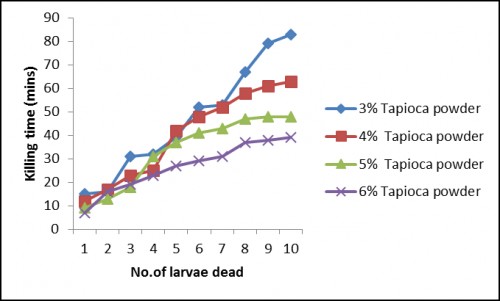

Fig. 4:

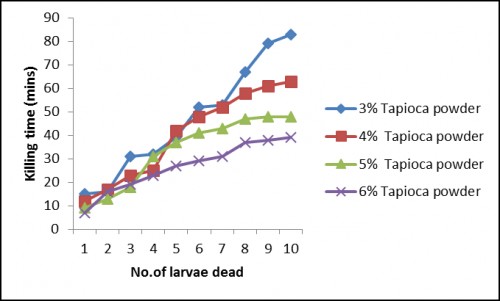

Fig. 4: Bioassay results of batch fermentation studies using different carbon sources (c) tapioca powder

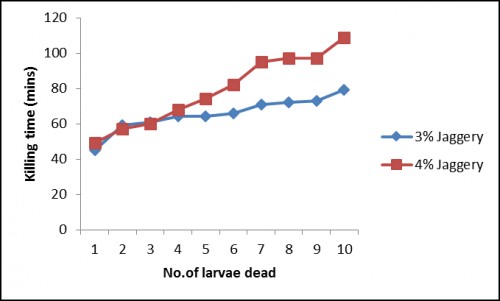

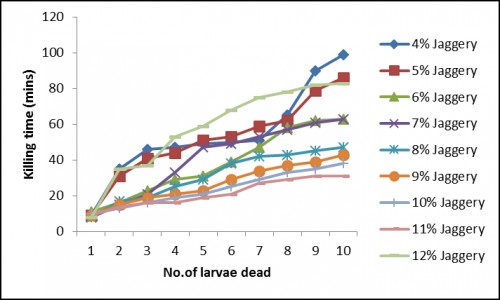

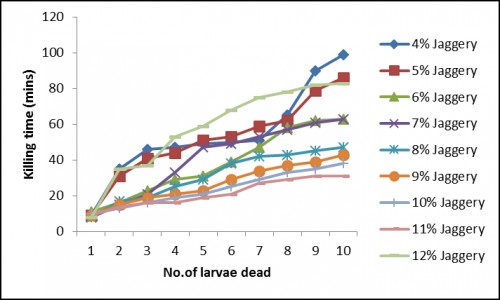

Fig. 5:

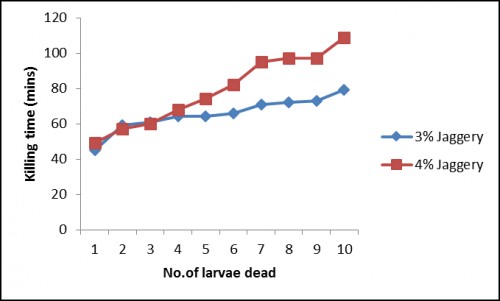

Fig. 5: Bioassay results of batch fermentation studies using different carbon sources (d) Jaggery

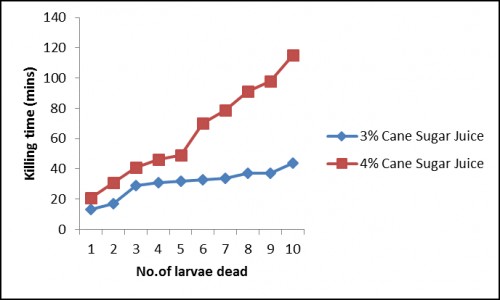

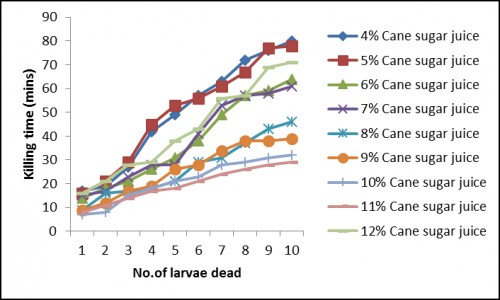

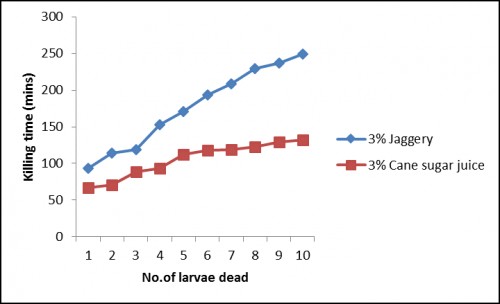

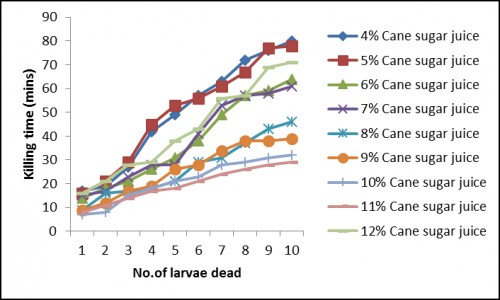

Fig. 6:

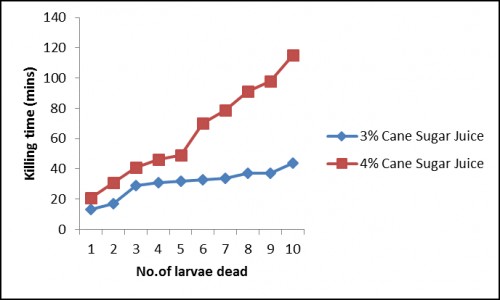

Fig. 6: Bioassay results of batch fermentation studies using different carbon sources (e) Cane sugar juice

Fig. 7:

Fig. 7: Larvicidal activity of

Bacillus thuringiensis subsp.

Israelensis for different carbon sources in fed-batch fermentation.

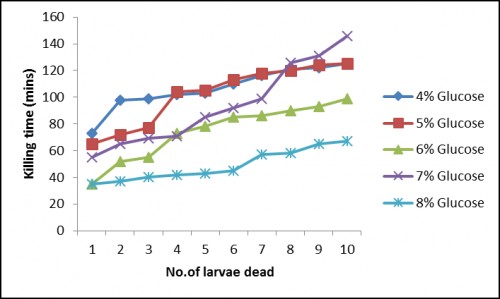

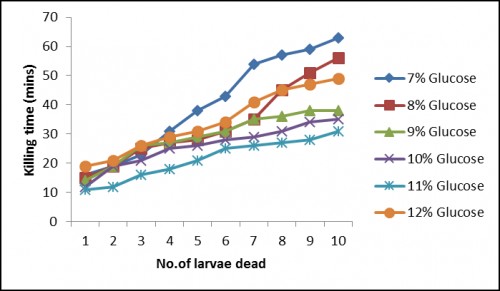

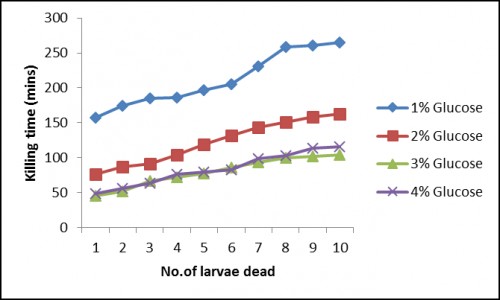

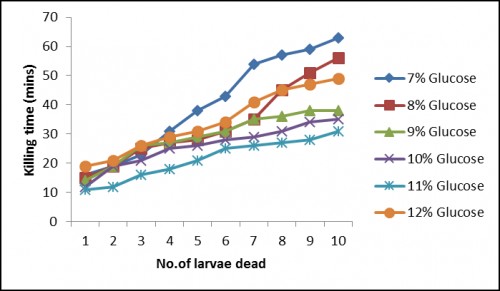

Fig. 8:

Fig. 8: Bioassay results of fed-batch fermentation studies (a) Glucose

Fig. 9:

Fig. 9: Bioassay results of fed-batch fermentation studies (b) Sucrose

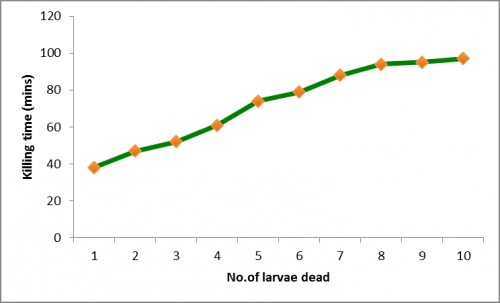

Fig. 10:

Fig. 10: Bioassay results of fed-batch fermentation studies (c) Jaggery

Fig. 11:

Fig. 11: Bioassay results of fed-batch fermentation studies (d) Cane sugar juice

Fig. 12:

Fig. 12: Bioassay results of fed-batch fermentations of Bti with different concentrations of glucose and 1% soyabean

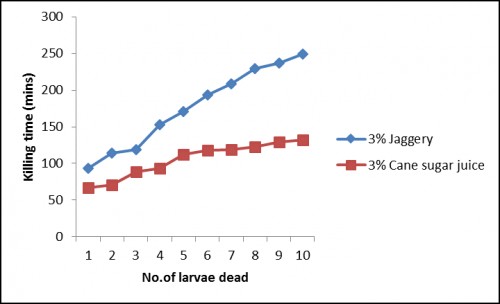

Fig. 13:

Fig. 13: Bioassay results of batch fermentations of Bti with different carbon sources (3% Jaggery and 3% cane sugar juice) without yeast extract

Fig. 14:

Fig. 14: Bioassay results of aeration studies of Bti with different carbon sources (3% Jaggery and 3% cane sugar juice) without yeast extract

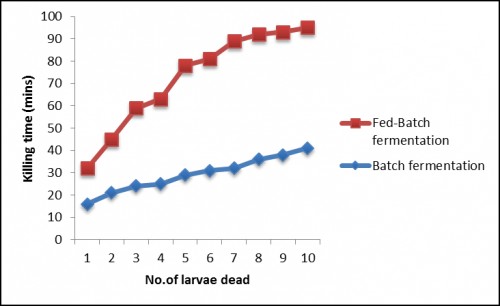

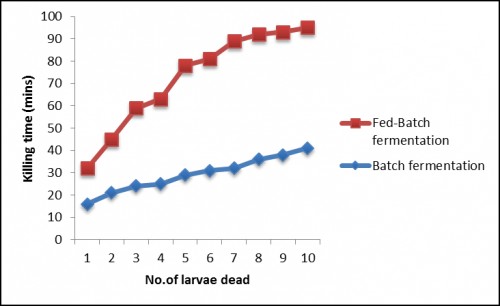

Fig. 15:

Fig. 15: Comparison of larvicidal activity between biomass obtained through batch (left) and fed-batch (right) fermentations of

Bacillus thuringiensis subsp.

Israelensis using increased aeration (high Kla value), and that obtained through normal aeration.

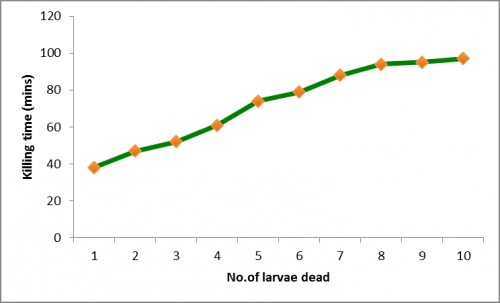

Fig. 16:

Fig. 16: Bioassay result of media containing 0.1% Calcium chloride

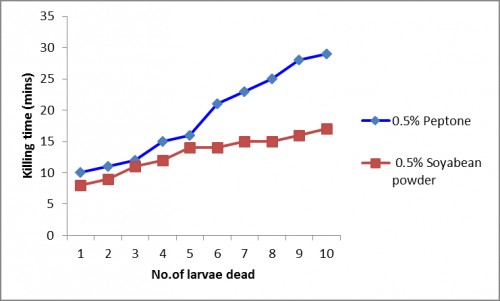

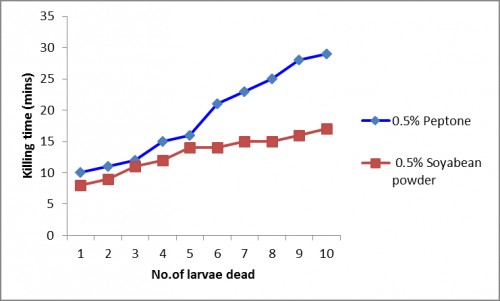

Fig. 17:

Fig. 17: Bioassay results of batch fermentations of Bti for observing effect of 0.1% Calcium carbonate with two different nitrogen sources as additive on sporulation

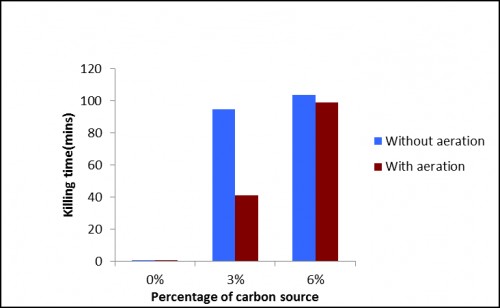

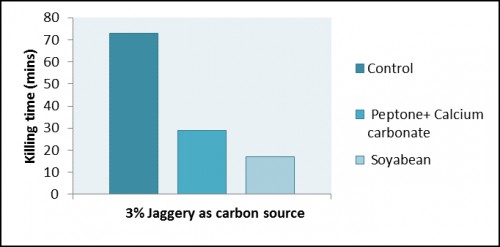

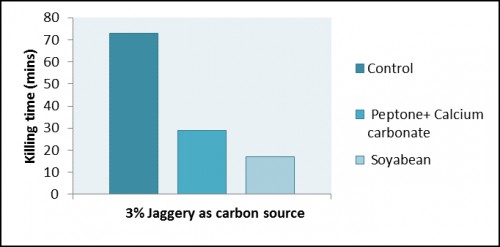

Fig. 18:

Fig. 18: Comparison of larvicidal activity between biomass obtained in batch fermentations without and with calcium carbonate.